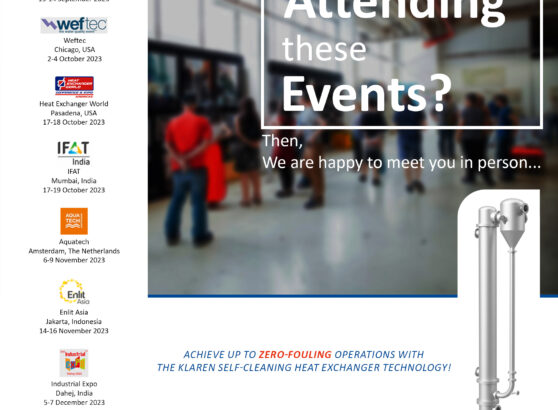

Continuous Cleaning of Heat Exchangers

Klaren Technology, a competence brand of Taprogge, offers continuous cleaning solutions for either new or existing heat exchangers. The KLAREN self-cleaning configuration can be realized in all manner of industries. A fluidized bed of solid particles is used at the tube side of the heat exchangers where the fouling liquid flows through. The solid particles create a scouring effect on the tube wall surface which removes the developing fouling layer. This prevents severe fouling of shell and tube heat exchangers. Our designs operate up to zero-fouling.

Learn More About the KLAREN Technology

Keep your equipment operational with the KLAREN technology. Vertical shell and tube heat exchangers operate with a clean surface, due to the application of a fluidized bed of cleaning particles. Conventional heat exchangers have the problem of severe fouling in the tubes. This can happen in just a matter of hours in severe cases. The cleaning particles will be continuously cleaning the walls of the heat exchanger tubes with a mild scouring effect. These cleaning particles have diameters of 1.6 to 4 millimetres and consist of glass, ceramic or metal. A constant heat transfer coefficient is maintained by cleaning the heat exchanger tubes at an early stage of formation. Moreover, these particles reduce pressure drop compared to conventional heat exchangers and enhance the heat transfer at lower liquid velocities. When the rate of removal of deposits by the particles exceeds the rate of precipitation of deposits, zero-fouling is guaranteed.

Services

Conduct Feasiblity Study

Design Self-cleaning Heat Exchangers

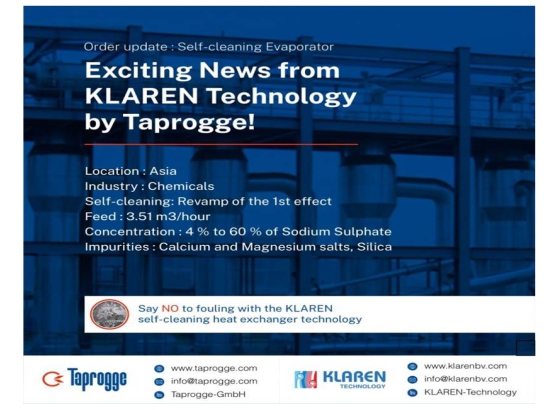

Revamp Heat Exchangers

Our Technology Can Be Utilized In Many Applications

Why Our Technology?

- The self-cleaning technology, can be applied in many industries and processes

- Global presence, innovative, focus on sustainability and innovation

- Experienced team available globally for visits and discussions

- KLAREN-system can be implemented in revamp or new case

- Only company in the world to provide fluidized bed cleaning solution

- Proven cases and experience across several industries

- High ROI with the savings in CAPEX and OPEX when using Klaren technology

- Experience with several fluids and types of fouling

Benefits of Continuous Cleaning of Heat Exchangers

Improved Energy Performance

Sustainable Process

Enhanced Production Capacity